Machining

Precise Production of Parts

and Contoured Tooling Surfaces

With over a century and a half of machining experience, the machining facility at Touchstone is making its mark in the aerospace, automotive and a variety of other industries.

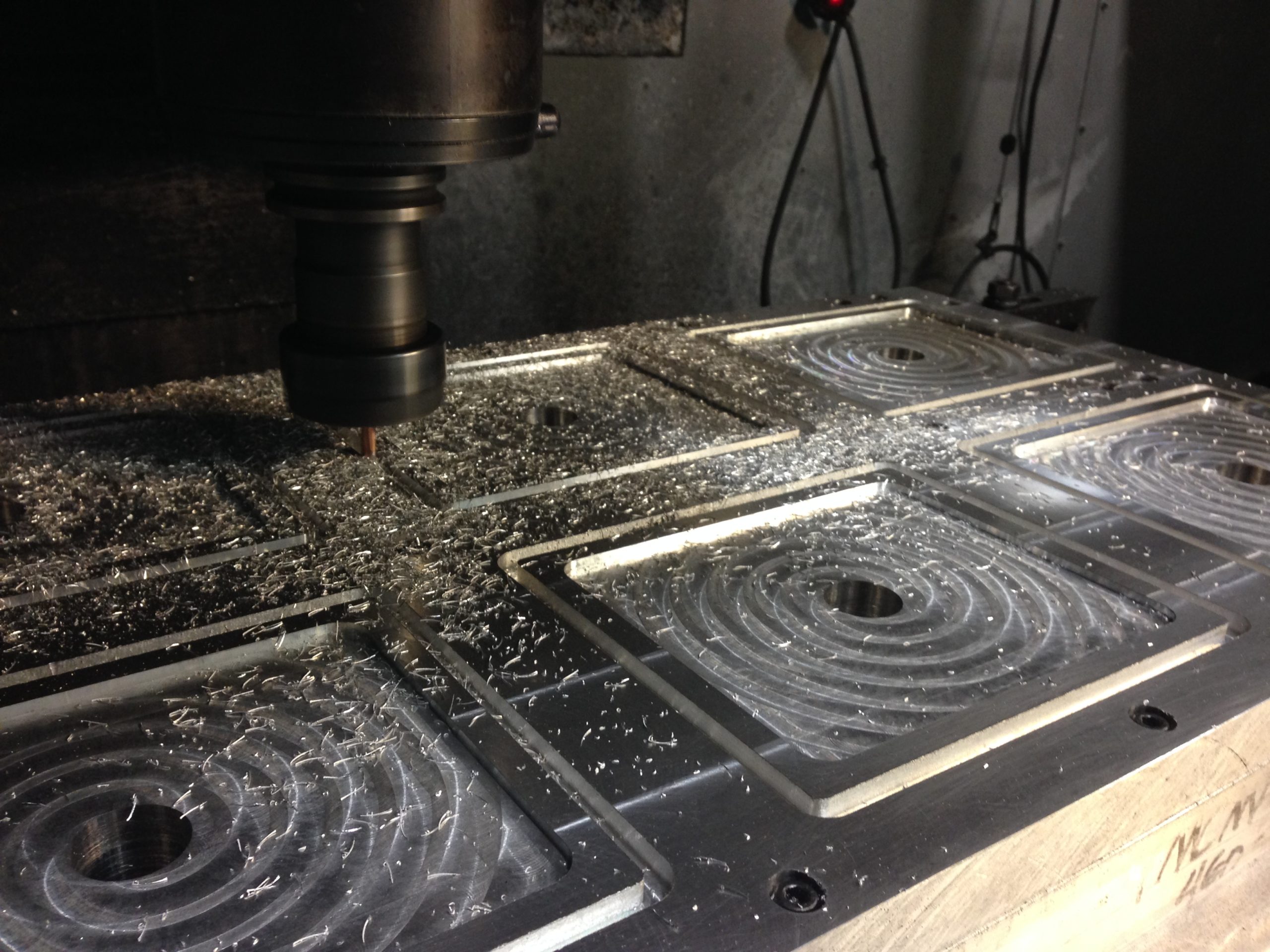

In 2015, Touchstone completed a new machining facility, which is equipped with four 5-axis CNC machining centers and one 3-axis router all located in a temperature-controlled environment for the precise production of parts and contoured tooling surfaces.

We are always looking to improve our processes and expand our services for our customers with the latest and most updated equipment. Recently, we have added a high-temperature autoclave in 2018 and a waterjet in 2021.

Four of the 5-axis machines are equipped with extremely high-resolution, positional scales. Combined with the temperature-controlled environment, these machines provide extraordinary precision for machining tolerances not possible by most companies.

Each mill is equipped with a robust dust collection that not only takes away the cutting swarf but also provides a positive pressure from above the machines to trap dust from escaping into the environment.

Three of the mills are equipped with coolant in addition to the dust collection.

While Touchstone has, in-house, the skill sets to modify, repair and calibrate the milling equipment, all 5-axis milling machines are certified by a world-class outside calibration service.

Touchstone personnel are skilled in the precise machining of composites, polymer foams, CFOAM carbon foam, steel, Invar®, aluminum, bronze, polymers, ceramic matrix composites, metal matrix composites, and most other materials.

“Touchstone personnel are skilled in the precise machining of composites, polymer foams, CFOAM carbon foam, steel, Invar®, aluminum, bronze, polymers, ceramic matrix composites, metal matrix composites, and most other materials.”