Carbon Backing Board

Highest-Quality CBB on the Market

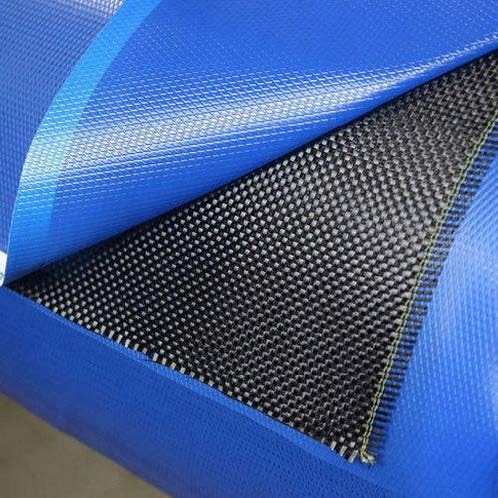

Carbon Backing Board (CBB) is a super-strong and durable plate or sheet with a variety of potential applications. As many boards like this are readily available on the market, we differentiate from our competitors by utilizing only the best materials and processes to provide our stiffest and highest-quality CBB. Typical board thickness is 1/4", but boards can be produced in any thickness needed.

Advantages

Low Porosity

High Tensile Strength

High Stiffness

High Temperature Resistance

Short Lead Time

Our Process

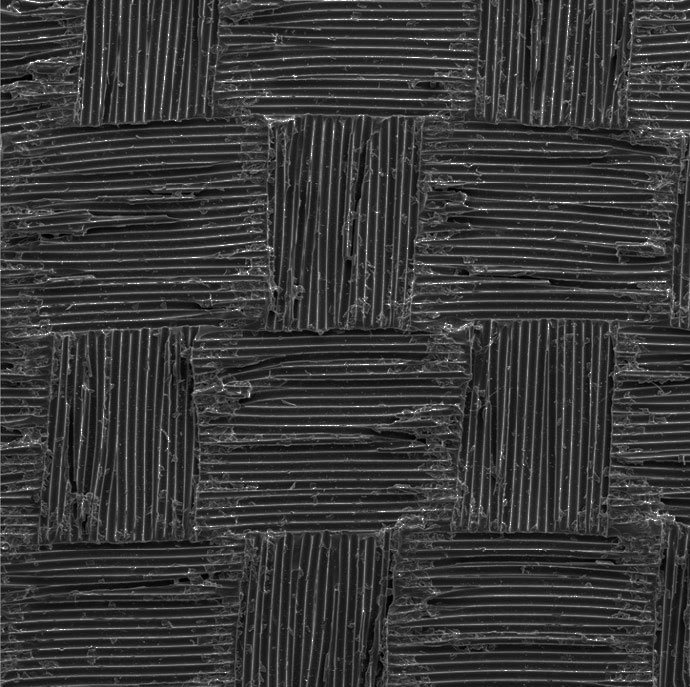

Use of Carbon Fiber Prepreg

- Layers of carbon fiber prepreg are laminated together and cured in an autoclave

- Allows higher mechanical properties, consistent base material, and better quality overall

- Minimizes potential defects in the final product

Autoclave Curing

- Proven to be more effective than alternatives

- Maintains low porosity and high stiffness

Surface

- Cured with a peel ply surface to allow for superior bonding and minimal to no preparation prior to use

- Remove peel ply and begin your bonding process

Waterjet Cutting

- Touchstone Advanced Composites is fully equipped for tooling design and has a waterjet division for taking projects to a finished state

- Potential finishing options include:

- CBB Only

- Complete egg crate, design, or assembly

- Turn-key tool

“Carbon fiber prepreg allows the CBB to display higher mechanical properties, more consistent base material and better quality overall.”

Applications

CBB can be used for a variety of applications and can be custom made to meet the needs of our customers.

Whether a partially or completely finished board is desired, Touchstone Advanced Composites has the capabilities to customize any project. Some applications include, but are not limited to, assembly jig, composite tooling, and carbon slip sheets.

Assembly Jig

- Low CTE

- High temperature resistance

- Made to easily go in and out of ovens

- Tested for up to 400°F

Composite Tooling

- Composite tools, also known as molds or egg crate, can be used as support structures

- PTM&W's 2846 high temperature resin or any high temperature epoxy laminating resin combines with 3" wide carbon tape to join the board to most tooling skins or other components

- End use of final structure determines bonding process

Carbon Slip Sheets

- A CTE matched plate can be made for curing applications

- Provides an easily sourced, cheaper, and lighter solution compared to traditionally used Invar

- Manufactured to any desired thickness by stacking piles

- Vacuum Integral

Spec Sheets

Overview

| Property | Test Method | Units | CBB (1/4" thick) |

|---|---|---|---|

| Tensile | ASTM D638 | KSI | 74.456 |

| Shear | ASTM D2344 | KSI | 8.35 |

| Compressive | ASTM D695 | KSI | 74.31 |

| CTE | ASTM E831 | μm/um°C | 2.28E-06 |

| Vacuum Integrity | Vacuum leak check | Holds vacuum |

Tensile

| Peak Stress (ksi) | Peak Load (lbf) | Peak Extension (in) | |

|---|---|---|---|

| Specimen 1 | 75.96 | 10125 | 0.2029 |

| Specimen 2 | 75.34 | 10043 | 0.1925 |

| Specimen 3 | 71.51 | 9603 | 0.1868 |

| Specimen 4 | 72.69 | 9801 | 0.1883 |

| Specimen 5 | 76.78 | 10332 | 0.2014 |

| Average | 74.456 | 9980.8 | 0.19438 |

Compressive

| Peak Stress (ksi) | |

|---|---|

| Specimen 1 | 68.03 |

| Specimen 2 | 73.62 |

| Specimen 3 | 73.99 |

| Specimen 4 | 84.48 |

| Specimen 5 | 71.41 |

| Average | 74.306 |

Shear

| Peak Stress (ksi) | |

|---|---|

| Specimen 1 | 7.57 |

| Specimen 2 | 8.31 |

| Specimen 3 | 9.05 |

| Specimen 4 | 8.8 |

| Specimen 5 | 8.02 |

| Average | 8.35 |