Metrology

Temperature-Controlled Inspection Facility

Tool building within the aerospace, automotive and shipbuilding industries requires a high degree of accuracy and repeatability.

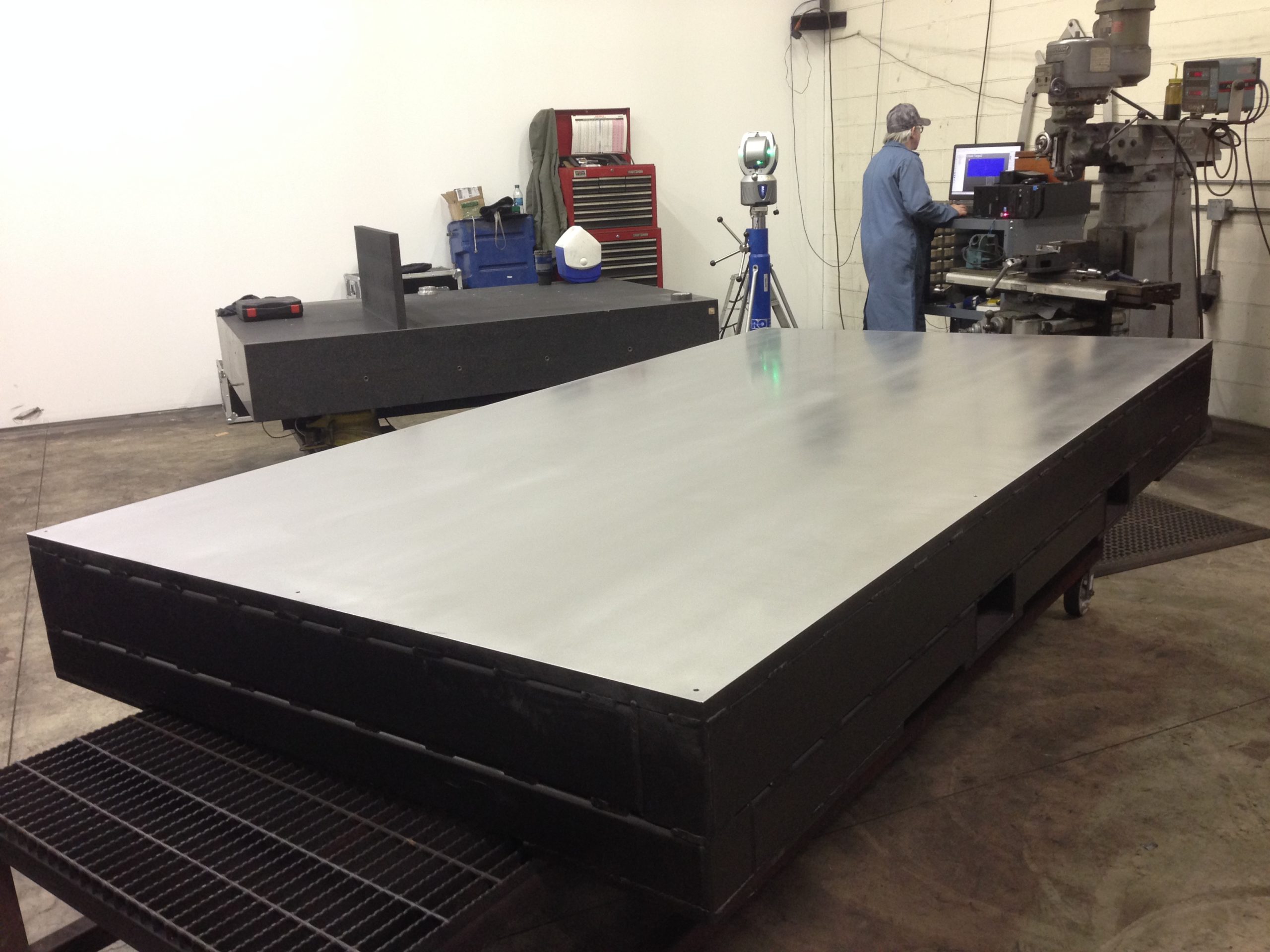

Touchstone has built a state-of-the-art, temperature-controlled inspection facility equipped with laser tracker, laser scanner and portable coordinate measuring machine (CMM) capabilities along with a host of traditional metrology and measurement tools operating in conjunction with multiple granite inspection tables and optical benches.

The laser tracker, laser scanner and CMM operate within the VeriSurf environment, which allows for a seamless integration with Touchstone’s CAM system.

Touchstone’s team of inspection personnel has decades of experience in the measurement of complex parts.

Capabilities include:

- Accurate measurements to less than ±.001″

- 3-D Models of parts that can be generated and compared to theoretical designs

- Reverse Engineering

- Laser-tracking inside milling envelope that can provide enhanced precision

Laser tracking small prototype reflector tool

Steel table inspection

Prototype composite tool inspection

“Touchstone has built a state-of-the-art, temperature-controlled inspection facility. Our team of inspection personnel has decades of experience in the measurement of complex parts.”