Production Tooling

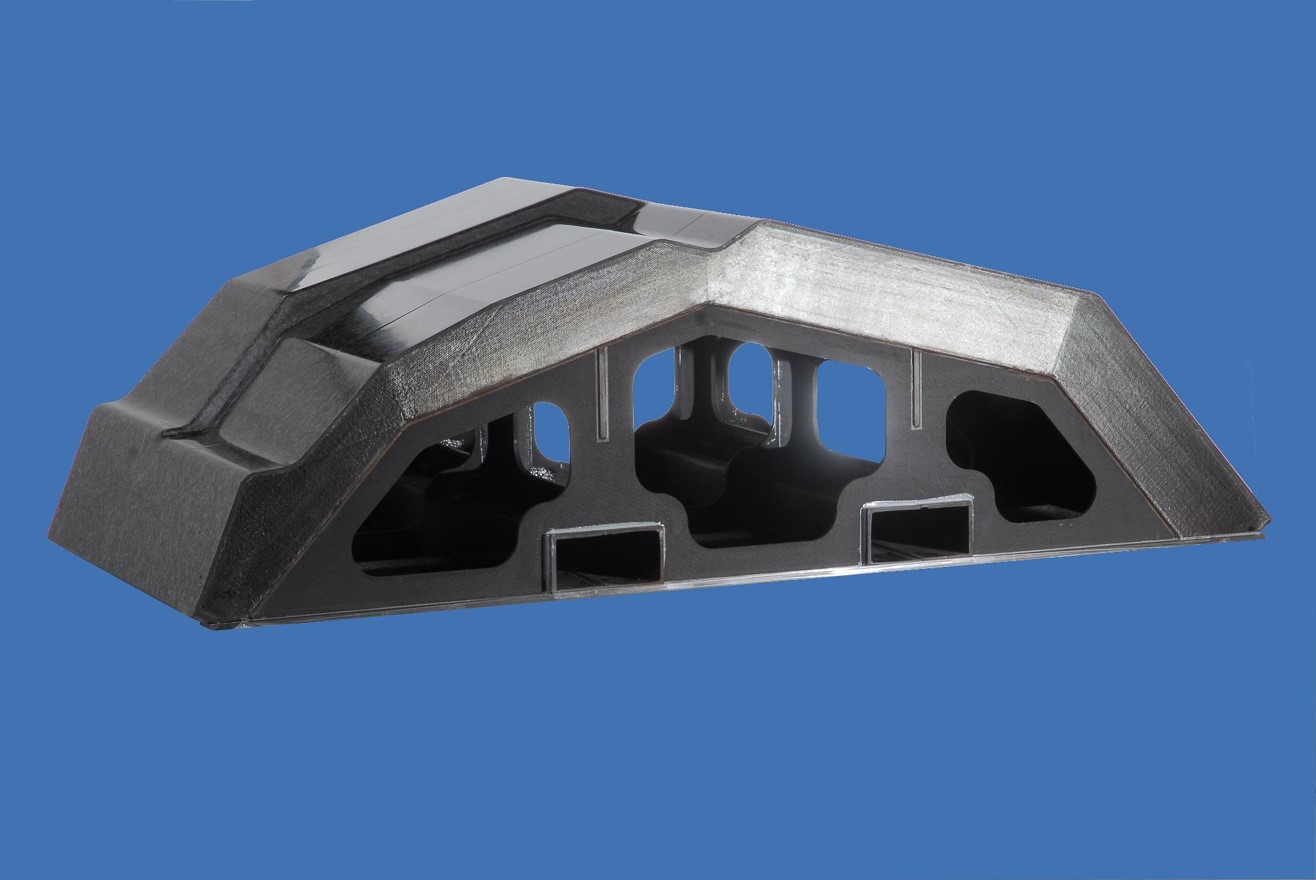

Egg Crate Composite Tooling

Reduced Cost, Increased Accuracy

Touchstone is equipped to produce traditional composite tooling ranging from low-temperature fiberglass tools to high-temperature 375 degree F carbon fiber/BMI aerospace cure tools.

CNC Patterns or master tools (source tools) are manufactured in our 5-axis machining centers and are laser tracked on a regular schedule to verify tolerances and ensure accuracy. By utilizing large CNCs, we are able to machine very large tools in a single setup that reduces costly seams, increases accuracy and reduces risk.

Transfers can be produced off our CNC Patterns utilizing a variety of laminate processes. Touchstone offers numerous construction methods allowing customers to optimize performance and cost relationships.

Lightweight CFOAM core composite tool

“By utilizing large CNCs, we are able to machine very large tools in a single setup that reduces costly seams, increases accuracy and reduces risk.”